Direct Metal Laser Sintering (DMLS) 3D Printing

Metal 3D Printing holds a unique position in modern-day product development. It allows for the direct manufacturing of complex end-use parts and facilitates tooling for conventional manufacturing technologies, reducing costs and lead times. This technology is also known as Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM).

Metal 3D Printing

Timeless Material Meets Limitless Technology

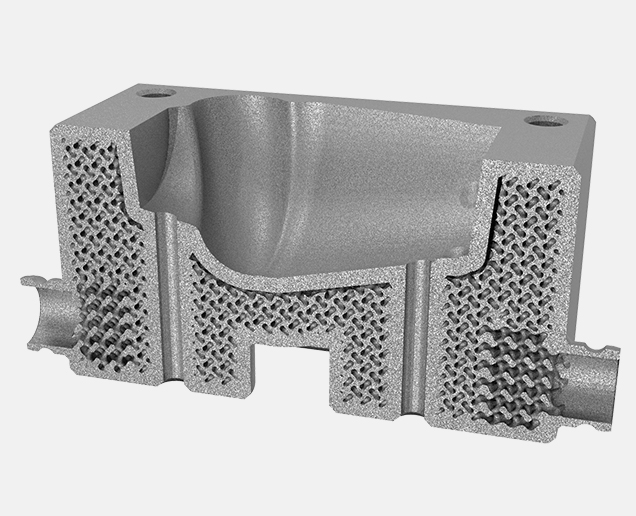

Direct Metal Laser Sintering (DMLS) is one of the few 3D printing technologies that directly create a metal part from its 3D computer model. DMLS shares the use of metal powders and lasers to print parts. This technology combines the design flexibility of 3D printing with the mechanical properties of metal. From tooling inserts with cooling channels to lightweight structures for aerospace, any application that involves complex metal parts potentially benefits from Metal 3D Printing.

-

Fully Functional Prototype

-

Conformal cooling channel in Injection molding dyes

-

Topology optimization

-

Heat exchanger and heat sinks

-

Complex assembly as a single part

Have any Questions or Suggestions? We would love to help you!

Technical Specifications

Build Size

- 10" x 10" x 10" (250 x 250 x 250 mm)

Standard Lead Time

- 5-7 working days

General Tolerances

- +/- 0.005” for the first inch is typical, plus +/- 0.002” for every inch thereafter

Layer Height

- .0012” - .0016" depending on material

Surface Roughness

- 150-400 µin Ra, depending on build orientation and material used for the build

Infill

- 100%

DMLS 3D Printing Materials

Aluminium

– Good strength and thermal properties with low weight

– Flexible post-processing possibilities

Stainless Steel

– Excellent strength, high ductility & good thermal properties

– Highly corrosion-resistant

Ready to get started on your DMLS 3D Printing Quote?

Free shipping on all 3D printing orders*

Advantages of DMLS 3D Printing

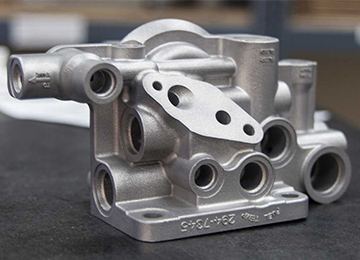

Printed parts with DMLS technology are durable, lightweight and precisely detailed.

- Print complex geometries with strong and durable components

- Rapid prototyping with high quality and high accuracy- ideal for functional testing

- Create complex shapes, intricate details and delicate features

- Reduce cost & development time by consolidating parts, no tooling required

- Build parts in a matter of hours

Applications of DMLS 3D Printing

Although the most popular industry that uses DMLS is the aerospace industry, other industries use the same process for different applications.

Aerospace

- Injectors

- Combustor liners

- Rocket engine manifolds

- Research efforts

- Functional prototypes

Medical

- Dental devices

- Surgical tools

- Orthopedic implant devices/prototypes

- Educational models

- Training tools

Energy

- Rotors

- Stators

- Mud Motors

- Turbine prototyping and research

- Bridge applications

Industrial

- Prototype tooling

- Manufacturing fixtures

- Low volume production

Have any Questions or Suggestions? We would love to help you!

DMLS Design Guidelines

Wall thickness

- Minimum thickness of 0.4 mm

Pin Diameter

- Minimum is 1 mm

- If smaller diameter is needed, reduce contour sharpness

Escape holes

- Holes are needed on hollowed metal parts so unmelted powder gets properly removed

- Bore hole diameter between 2 and 5 mm is suggested

Support/Overhangs

- Support is necessary in all situations

Unsupported Walls

- 0.5 mm is the maximum length a cantilever-style overhanging surface can be

Aspect Ratio

- Maximum ratio is 8:1 Between the vertical print height and part section. This is yo stabilize the printed part on the build plate

Tolerances

- Part tolerance is ± 1mm -layer thickness in print direction

- 0.127 mm is attainable in the XY plane

Minimum Features

- 0.6 mm required

Embossed/Engraved Details

- 0.1 mm wide/high

Limitations of DMLS 3D Printing

As the cost is often higher with both machines and materials, using this technique is not often fit for producing high volume orders. Design also is a limitation when using DMLS. This is because not all applications designed when using traditional manufacturing can be converted to a additive manufacturing solution. More restrictions when using DMLS is product size. Most machines, even large machines, have a small build size volume. The average build volume size is 250 mm x 250 mm x 300 mm. Furthermore, machines are very complex to use, coming in industrial sizes and strict operating, material handling, post processing and maintenance procedures.

DMLS Post-Processing

The most frequently used post processing methods are the following;

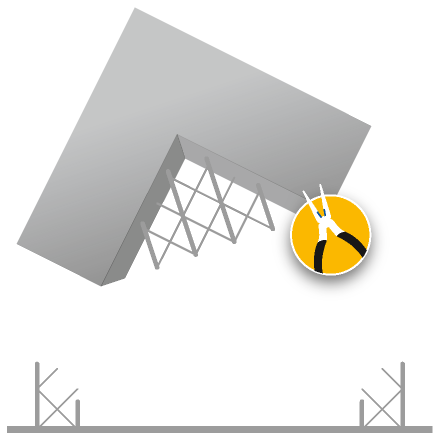

- Surface treatment

- Support removal

- Heat treatment

- Machining

Have any Questions or Suggestions? We would love to help you!

How does Metal 3D Printing work?

The 3D model

A laser melts metal particles together

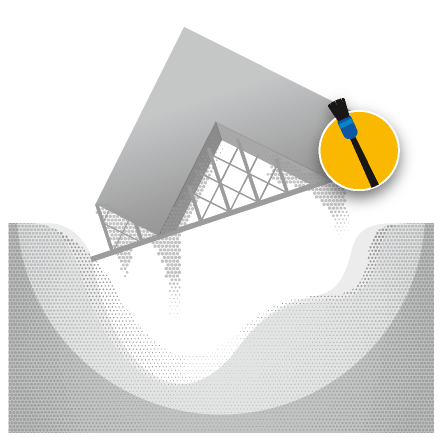

Successive layers of metal powder are spread on top, while a laser selectively binds particles to form the part and its support

The loose powder is removed

The part undergoes heat treatment

A laser melts metal particles together

The part is finished